Top 7 things that we are aware about the repair and maintainance of our projects

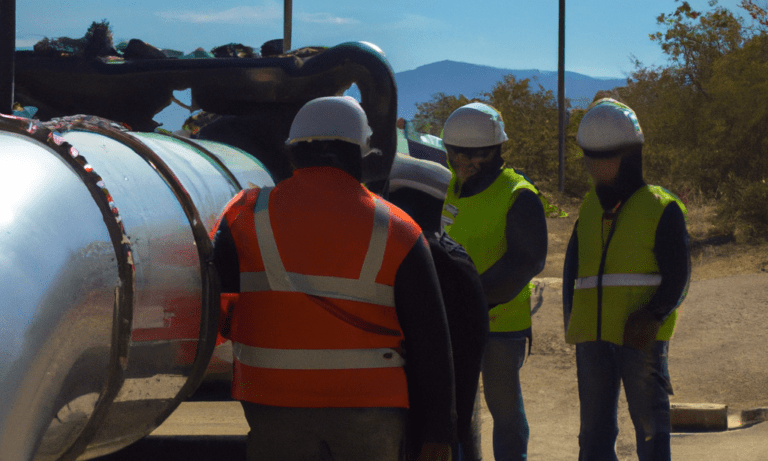

Pipeline services play a crucial role in the oil and gas industry, transporting millions of barrels of crude oil and natural gas every day. It is imperative that these pipelines are properly maintained and repaired to ensure the safe and efficient transportation of these resources. In this blog, we will discuss the importance of pipeline repair and maintenance and provide tips for effective pipeline management.

Pipeline repair and maintenance is crucial for the following reasons:

Importance of regular maintenance: Regular maintenance can help prevent leaks, increase the lifespan of pipes, and improve the overall efficiency of the system.

Types of PPR pipe damage: Common types of damage to PPR pipes include cracks, leaks, and deformations. Understanding the cause of the damage is key to determining the best repair method.

Repair methods: Different repair methods are available for different types of damage. Some common methods include patching, welding, and replacing damaged sections.

Tools and materials: To carry out repairs, it is important to have the right tools and materials. A list of required tools and materials, as well as tips on where to purchase them, could be included in the blog.

DIY vs professional repair: Depending on the severity of the damage, repairs may be able to be carried out by a DIY enthusiast or may require the assistance of a professional plumber. The blog could explore the advantages and disadvantages of both approaches.

Safety measures: When working on PPR pipes, it is important to take safety precautions. The blog could include tips on how to avoid hazards and what safety equipment to use.

Maintenance tips: To help keep PPR pipes in good condition, the blog could include tips on how to maintain them, such as avoiding exposing pipes to extreme temperatures and avoiding heavy loads.

Tips for Effective Pipeline Management

Regular Inspections: Regular inspections of the pipeline are crucial to identifying potential issues and preventing them from becoming more serious.

Proper Documentation: Keeping detailed records of the pipeline’s condition, maintenance, and repair work is important for future reference and decision making.

Employee Training: Regular training of employees is crucial to ensuring that they are equipped with the necessary skills and knowledge to carry out effective pipeline management.

Use of Technology: The use of technology, such as pipeline management software and remote sensing, can help identify potential problems early and reduce the risk of accidents and leaks.

Conclusion

Effective pipeline management is crucial for the safety and reliability of oil and gas transportation. Regular maintenance and repair work, along with proper documentation, employee training, and technology, can help ensure that pipelines are operating at their best. By following these tips, pipeline companies can ensure the long-term health and success of their pipeline services.