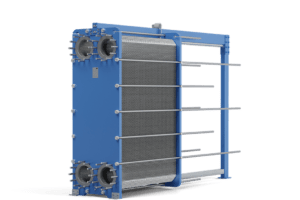

Introduction: Plate heat exchangers are highly efficient devices used in a wide range of industries to transfer heat between two fluids. With their compact design, high heat transfer rates, and versatility, plate heat exchangers have become indispensable in various applications. In this blog, we will explore the working principle, advantages, and common uses of plate heat exchangers, shedding light on their role in enhancing efficiency and heat transfer.

- Understanding Plate Heat Exchangers:

- Explaining the basic concept of plate heat exchangers, which consist of a series of plates with alternate fluid channels.

- Describing how heat is transferred between the two fluids as they flow in separate channels, allowing for efficient heat exchange.

- Operating Principles:

- Detailing the counterflow or parallel flow configuration options for plate heat exchangers, highlighting their impact on heat transfer efficiency.

- Discussing the use of gaskets or brazing to seal the plates, ensuring proper fluid separation and preventing leakage.

- Advantages of Plate Heat Exchangers:

- Highlighting the compact design of plate heat exchangers, which allows for efficient use of space and easy integration into existing systems.

- Exploring the high heat transfer coefficients achieved through the large surface area of the plates, maximizing thermal efficiency.

- Discussing the flexibility in adjusting plate arrangements and adding or removing plates to accommodate varying heat transfer requirements.

- Common Applications:

- Discussing the diverse range of industries where plate heat exchangers find applications, such as HVAC systems, refrigeration, chemical processing, food and beverage, and power generation.

- Exploring specific uses, such as heat recovery, cooling and heating processes, oil cooling, condensation, and evaporation.

- Factors to Consider:

- Highlighting important considerations when selecting a plate heat exchanger, including flow rate, temperature range, pressure drop, material compatibility, and maintenance requirements.

- Emphasizing the need to choose the appropriate plate material, such as stainless steel or titanium, based on the nature of the fluids and operating conditions.

- Maintenance and Troubleshooting:

- Providing guidelines for routine maintenance, including regular cleaning and inspection of the plates to maintain optimal heat transfer efficiency.

- Offering troubleshooting tips for common issues, such as fouling, scaling, or clogging, and addressing the importance of addressing these problems promptly.

- Energy Efficiency and Environmental Benefits:

- Exploring how plate heat exchangers contribute to energy conservation by facilitating heat recovery, reducing energy consumption, and lowering greenhouse gas emissions.

- Discussing the environmental advantages of plate heat exchangers, such as minimizing water usage and enabling more sustainable processes.

Conclusion: Plate heat exchangers play a vital role in enhancing heat transfer efficiency across various industries. With their compact design, high thermal efficiency, and flexibility, they provide a cost-effective solution for heat exchange applications. Understanding the working principles, advantages, and proper maintenance of plate heat exchangers is key to maximizing their performance and reaping the benefits of improved energy efficiency and environmental sustainability.