A-Z everything you should know about injection moulding machines (IMM)

For the first time in South India, Closed loop PHE based cooling water system was designed. And, we installed it for the Injection Moulding Plant at SOUTHERN POLYMERS, Thirumazhisai . We designed intermediate heat exchanger to avoid cooling tower raw water engineering to the Injection Moulding oil cooler and mould. This design ensures sustainable use of the oil cooler and maintains clean as new for moulds.

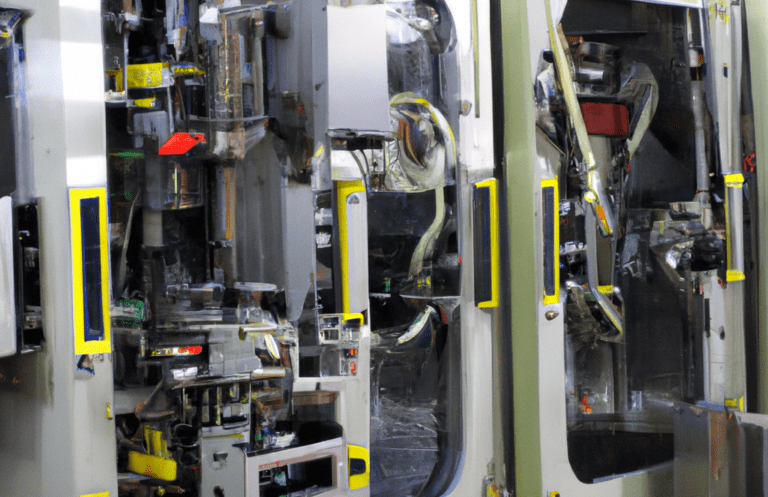

WHAT ARE INJECTION MOULDING MACHINES?

Injection moulding machines are widely used in the manufacturing of a variety of products including plastic toys, household items, automotive components, and medical devices. The technology behind this machine is simple yet highly effective. Here’s a closer look at how injection moulding works and the different types of machines available in the market.

The Process of Injection Moulding:

The process of injection

Material preparation: Plastic pellets or granules are melted in the hopper of the injection moulding machine. The melted moulding involves the following steps: material is then transferred to the injection unit, where it is forced through a nozzle into a mould. Clamping: The mould is then closed and clamped under high pressure. Injection: The melted plastic is injected into the mould through the nozzle.

Cooling: Once the plastic has been injected, it is allowed to cool down and harden.

Opening: The mould is then opened and the finished product is removed.

Types of Injection Moulding Machines:

There are two main types of injection moulding machines: hydraulic and electric.

Hydraulic Injection Moulding Machines: These machines are powered by hydraulic pressure and are capable of producing large and heavy parts. They are known for their high speed and efficiency.

Electric Injection Moulding Machines: Electric injection moulding machines are powered by electricity and are known for their precision and accuracy. They are used for making smaller and lighter parts.

CONCLUSION:

Injection moulding machines are an essential tool for many industries and it plays a significant role in the production of a wide range of products. Whether you are a manufacturer looking to increase efficiency and production, or a consumer looking for high-quality plastic products, you will benefit from this technology.